Streamlining multi-scale modeling: a BPMN-based no-code approach for simulation workflows

-

Organization: MUSICODE

-

Design challenge: Translate MODA workflows into executable multi-scale modeling workflows

-

Benefits:

Implement executable multi-scale simulation workflowsReduce debugging time and reuse of simulation modelsModel BPMN data elements quickly

MUSICODE, an EU research project, aims to create an Open Innovation Platform for OLAE applications. Faced with the challenge of translating theoretical modeling into executable multi-scale modeling workflows, MUSICODE turned to Cardanit for a solution.

By leveraging the BPMN standard and Cardanit's intuitive editing features, MUSICODE streamlined the process, enabling modelers to effortlessly transform MODA workflows into executable simulations, all without writing a single line of code. This innovative approach improves workflow efficiency, fosters greater collaboration, and accelerates progress in the field of materials modeling.

The ContextBringing OLAE innovation with BPMN and multi-scale modeling

MUSICODE is a European research project funded by the European Union’s Horizon 2020 research and innovation program. It’s coordinated by the University of Ioannina and counts 11 partners from both academia and industry, including TinniT Technologies. The goal of MUSICODE is to create an Open Innovation Platform for Materials Modelling in the Organic and Large Area Electronics (OLAE) application domain.

OLAE is a rapidly emerging sector bringing disruptive technological revolutions in energy, electronics, transport, photonics, buildings, lighting, and displays. It also impacts health, wearables, the IoT, and agriculture. OLAE devices are manufactured on flexible polymer web rolls. They represent complex architectures of multilayer stacks of organic, polymer, inorganic, and hybrid nanomaterials.

MUSICODE aims to create multi-scale modeling workflows and address specific problems in organic photovoltaic device development and fabrication. These devices also go by the name of organic solar cells. MUSICODE chose the BPMN standard to design the modeling workflows, and here is where Cardanit comes into play.

The ChallengeFrom MODA workflows to executable workflows

In the field of materials modeling, modeling workflows are usually documented using the so-called MODA workflows. MODA (which stands for MOdelling DAta) is a template for the standardized description of materials models, meant to guide users towards a complete high-level documentation of materials models, starting from the end-user case to the computational details.

A MODA workflow is not executable. So, it needs to be implemented to be simulated. This means either developing the code from scratch to link solvers and data sources together, or facilitating the implementation using an integration framework like the Multi-Physics Integration Framework (also known as MuPIF). Both options require writing some amount of code and having some knowledge about software development. In this context, a no-code approach could make it easier for modelers to go from MODA workflows to executable workflows. This is one of the core ideas of the Open Innovation Platform developed in MUSICODE.

The SolutionMapping MODA workflows to BPMN processes

The MUSICODE no-code approach is based on BPMN since MODA workflow parts naturally map BPMN elements. Cardanit has been selected to implement the MUSICODE workflow editor, given its user-friendly editing tools and strong adherence to the BPMN standard.

The integration of Cardanit into the MUSICODE Open Innovation Platform enables fully automated simulation case studies.

Thanks to Cardanit, modelers can easily map their MODA workflows to BPMN processes. Tasks within these processes represent physics-based simulation models available in the Open Innovation Platform, while data elements describe the data exchanges between them. Once a BPMN process is complete, the backend service of the Open Innovation Platform can process its XML standard representation to generate the Python code for running the workflow via MuPIF.

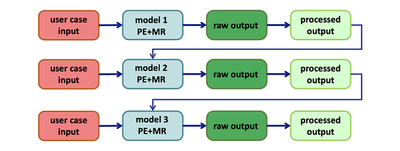

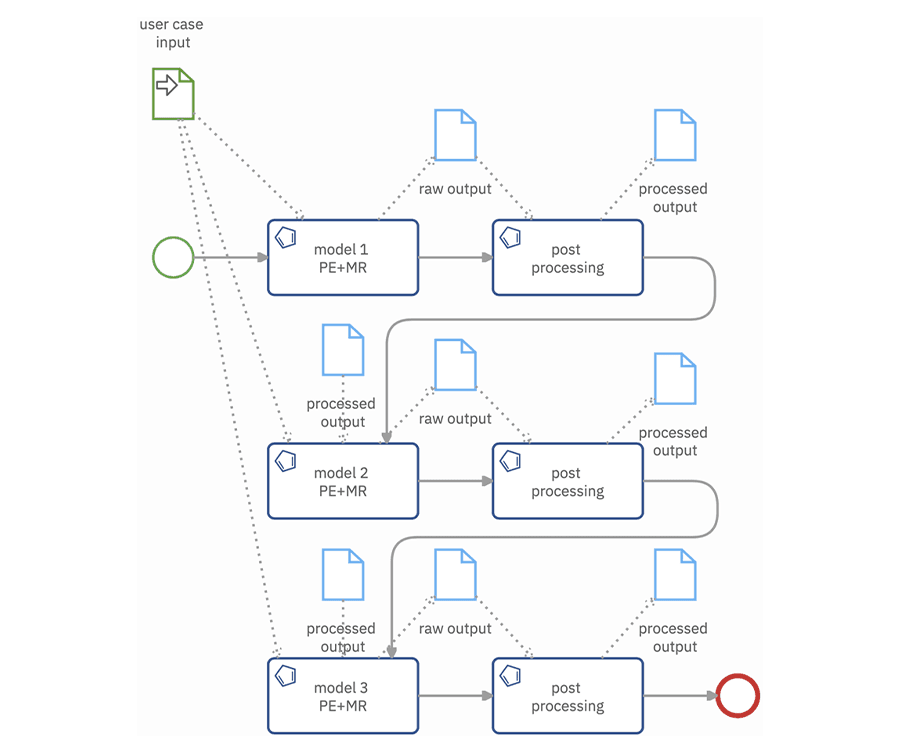

A BPMN diagram of a mapped MODA workflow using a customized version of Cardanit

The BenefitsNo-code approach for efficient implementation of multi-scale simulation workflows

Modelers using the MUSICODE Open Innovation Platform can implement executable multi-scale simulation workflows without writing a single line of code. This allows them to put all the focus on the interaction between the simulation models. The no-code approach developed with Cardanit can lead to savings in terms of reduced debugging time and reuse of simulation models.

With the help of Cardanit, we managed to implement a quick setup and run simulation studies with parameter variations. The small amount of additional time required for creating the workflow graphically is more than compensated for by the savings gained from automating the simulation runs with the MUSICODE platform.

Multi-scale modeling workflows can have a high number of data exchanges between simulation models. This results in managing a high number of Data Inputs, Data Outputs, and Data Associations in the corresponding BPMN process. To correctly convert the BPMN process into Python code, it’s important to set all the bits and pieces of the BPMN data elements correctly. This task, usually daunting and error-prone, becomes quick and easy thanks to the Cardanit Data Flow tool, as the MUSICODE partner TinniT explained.

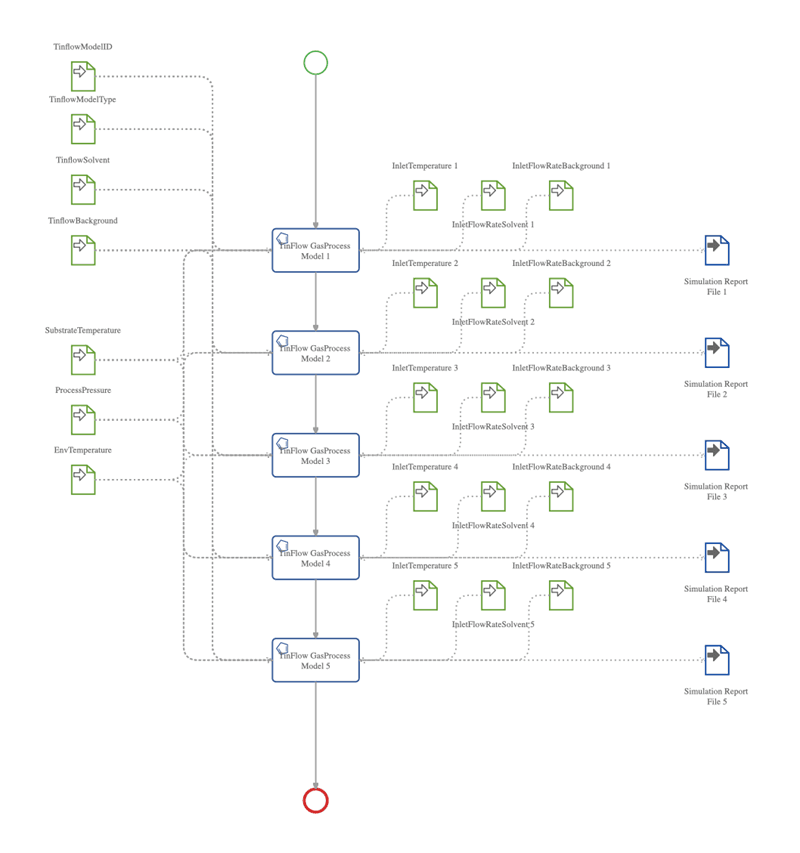

Multi-scale modeling workflows for simulation studies drawn by Tinnit with Cardanit Data Flow Tool

The figure above shows the multi-scale simulation workflow TinniT created for the Organic Vapour Phase Deposition (OVPD) fabrication of OLEDs. The workflow involved connecting five tasks in series and configuring them with the appropriate simulation models. Using the Data Flow tool, TinniT quickly set up the required input items to match the Data Input task requirements. They sorted the data elements, placing process parameters, which were the same for all simulation runs, graphically on the left-hand side of the workflow. Each of these items was linked to all five tasks. Then, they organized the parameters to be varied for the study on the right-hand side. Subsequently, they assigned a Data Output (simulation report file) to each task. Finally, after designing the simulation workflow and generating the corresponding MuPIF Python code, TinniT started the simulation study in the MUSICODE Open Innovation Platform by adjusting parameter values.

We successfully used Cardanit for CFD simulation studies based on the TinFlow software.

Aron Kneer has a PhD in Engineering from Karlsruhe Institute of Technology (KIT), Germany. His professional journey began as a Project Engineer at Battelle Institute in 1989. In 2001, he founded TinniT Technologies, where he continues to serve as Managing Director, focusing on research and development. From 2018 to 2020, Aron engaged in a research collaboration with the University Abomey-Calavi, Benin, in the field of solar technology, fine dust absorption systems, simulation (CFD) and measurements.

Aron Kneer has a PhD in Engineering from Karlsruhe Institute of Technology (KIT), Germany. His professional journey began as a Project Engineer at Battelle Institute in 1989. In 2001, he founded TinniT Technologies, where he continues to serve as Managing Director, focusing on research and development. From 2018 to 2020, Aron engaged in a research collaboration with the University Abomey-Calavi, Benin, in the field of solar technology, fine dust absorption systems, simulation (CFD) and measurements.

Klaus Reimann holds a Diploma in Aerospace Engineering, earned in 1995. His professional journey began as an Assistant at the Institute for Statics and Dynamics of Aerospace Structures at the University of Stuttgart. From 2001 to 2017, Klaus served as a Managing Director at FemScope, focusing on research and development, education, and software development for aerospace, automotive, and civil engineering. Currently, he applies his expertise as a Research and Development Engineer at TinniT Technologies, Karlsruhe.

Klaus Reimann holds a Diploma in Aerospace Engineering, earned in 1995. His professional journey began as an Assistant at the Institute for Statics and Dynamics of Aerospace Structures at the University of Stuttgart. From 2001 to 2017, Klaus served as a Managing Director at FemScope, focusing on research and development, education, and software development for aerospace, automotive, and civil engineering. Currently, he applies his expertise as a Research and Development Engineer at TinniT Technologies, Karlsruhe.

Dario Campagna joined ESTECO in 2012 after earning a PhD in Computer Science. Starting as a Developer in the Research and Development (R&D) team, he soon took on roles as Scrum Master and Agile Coach, fostering continuous improvement across the organization and engaging in Business Process Management research. Since September 2021, he has been overseeing EU and regional projects, along with internal research initiatives, applying his expertise in agile methodologies. In 2023, Dario got promoted to Head of R&D.

Dario Campagna joined ESTECO in 2012 after earning a PhD in Computer Science. Starting as a Developer in the Research and Development (R&D) team, he soon took on roles as Scrum Master and Agile Coach, fostering continuous improvement across the organization and engaging in Business Process Management research. Since September 2021, he has been overseeing EU and regional projects, along with internal research initiatives, applying his expertise in agile methodologies. In 2023, Dario got promoted to Head of R&D.

Learn how to effectively represent data in your BPMN diagrams, create reliable data models and design processes that align with your organizational goals.

Do you know how to model data in BPMN?

Learn how to effectively represent data in your BPMN diagrams, create reliable data models and design processes that align with your organizational goals.

Do you know how to model data in BPMN?

Learn how to effectively represent data in your BPMN diagrams, create reliable data models and design processes that align with your organizational goals.