Embracing BPMN and DMN for better informed decisions in the composite materials design

-

Organization: COMPOSELECTOR

-

Design challenge: Embrace decision and process modeling within a single framework

-

Benefits:

Integrate material modeling with business process modelingBetter risk assessment and increased design qualityCollaborate with all stakeholders

Cardanit’s collaborative features, user-friendly interface, and compliance with the BPMN 2.0 and DMN standards helped develop an innovative approach to composite design and manufacturing process, enhancing informed decision-making across departments. Here’s how Cardanit helped tackle this daunting task effectively in the framework of the EU-funded project COMPOSELECTOR.

The ChallengeEmbrace decision modeling and process modeling within a single framework

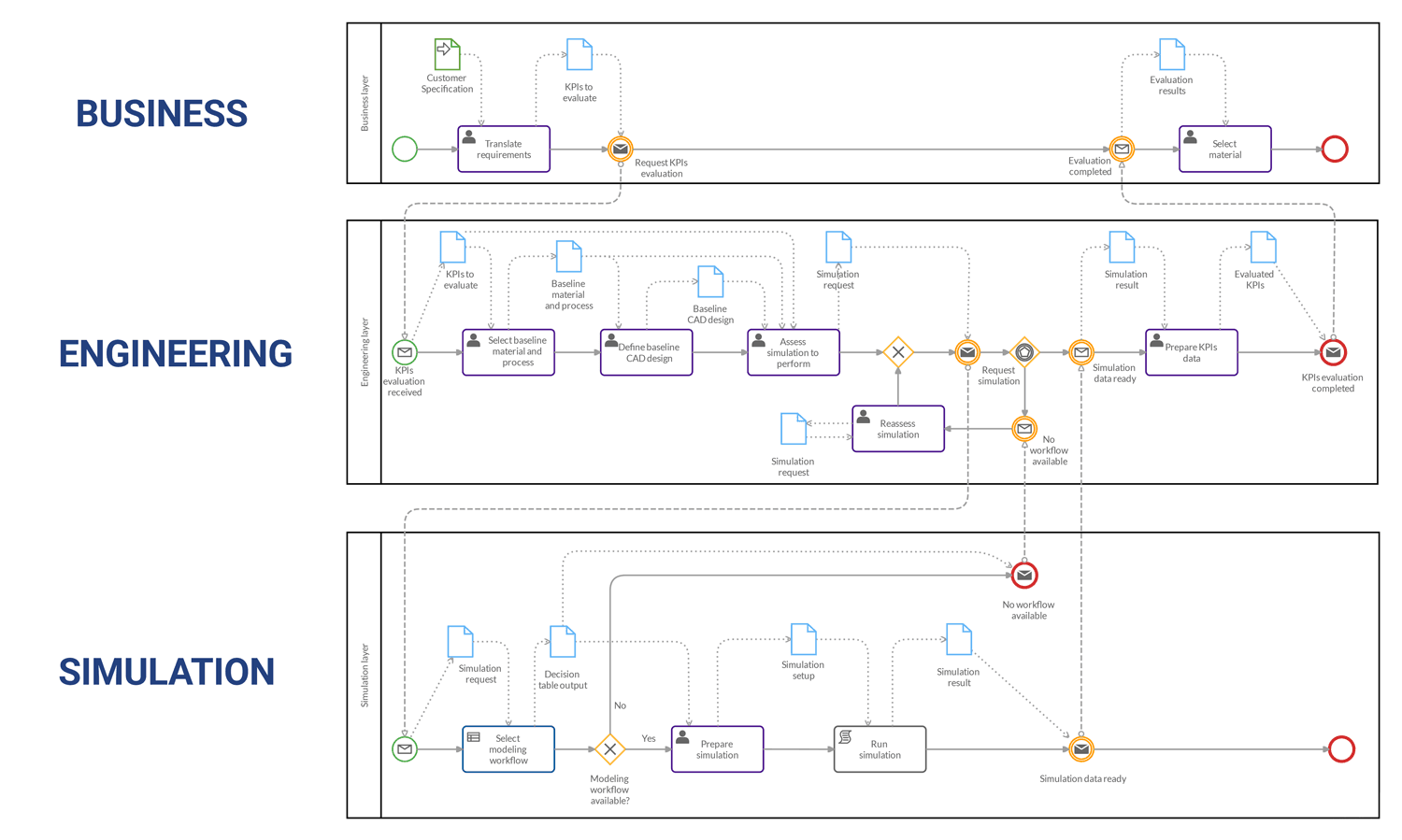

Complex operational decisions are the norm when it comes to composite materials design and manufacturing. In fact, the decision-making in the composites design process happens at three levels: business, engineering, and simulation. To deliver competitive solutions in such a complex industry, these three levels need to interact and integrate smoothly and seamlessly from the earliest stages of the process.

Here’s how Cardanit helped tackle this daunting task effectively in the framework of the EU-funded project COMPOSELECTOR.

Composites like carbon fiber and glass-reinforced plastic are nowadays used in many commercial products - from airplane wings and fuselages to vehicle tires and bicycle frames, to name a few. Replacing steel and other alloys with composites can lead to improvements in product performance and improved usability. But this comes at a cost.

Composite materials are in fact more expensive than traditional ones, increasing the need for cost-effective decisions early in the process.

The selection of new materials for a product needs to take into account different types of requirements and involves multiple decision-makers across departments.

The knowledge about the underlying process is often scattered inside the organization with no single source of truth nor a shared representation for such knowledge

This makes the management of the process difficult, if not impossible.

Business decision-makers need access to tailored data from the engineering departments to make informed, timely decisions.

Meanwhile, engineering departments need timely input from the management to leverage numerical models and simulation software in the most effective way.

Different types of requirements need to be considered simultaneously starting from the early stages of design in order to deliver a competitive solution at the right moment.

The SolutionA tailored Business Decision Support System (BDSS) based on Cardanit

As mentioned above, the decision-making process in the composite material design happens at three levels: business, engineering, and simulation.

This insight shaped the way materials modeling was coupled to business process and decision management in the EU-funded project COMPOSELECTOR, where Cardanit was used as the tool of reference for business and decision process modeling.

With the help of Cardanit, we, as COMPOSELECTOR project partners, developed a Business Decision Support System (BDSS) that integrates material modeling with business process modeling within a single framework.

BDSSs are information systems that support and facilitate business decision-making processes. With a BDSS we can represent and store knowledge about existing decision processes. The BDSS can then use this knowledge to orchestrate processes and help people make informed decisions.

In the BDSS business processes are modeled using the Business Process Model and Notation 2.0 (BPMN) standard. Decisions are represented using the Decision Model and Notation 1.3 (DMN) standard.

The availability of a single, interdisciplinary business process and decision workflow leads to better risk assessment, seamless knowledge sharing, cost reduction, and finally, increased design quality.

Collaboration is key: breaking silos with Cardanit collaboration features

In the preliminary development phase, we used Cardanit to model the business and decision processes underlying three application cases coming from the project’s industrial partners.

Starting from textual descriptions of processes we created hierarchical top-down BPMN models. We adopted an iterative approach. Each iteration added details to the model and helped in building a shared understanding of the process.

The collaboration features of Cardanit fostered conversation on the business process. It was key to the success of the application case analysis.

Business analysts and composite materials experts worked together throughout each of the iterations, sharing models and editing them in real-time.

BPMN models turned out to be both a knowledge representation tool and a tool for having conversations.

The BPMN models obtained with this iterative process collect all the knowledge about existing processes in a single cloud-based repository that can be updated in real-time and accessible by all the stakeholders anytime from any place.

In some cases, this knowledge was spread between different people in the industrial partner organization. Cardanit fostered conversations centered on BPMN models between those people too.

The BenefitsReal-life application cases at the heart of COMPOSELECTOR

Three real-life application cases guided the development of COMPOSELECTOR - material and process selection of fuselage thermoplastic frame (Airbus), material and process selection of a leaf-spring (Dow), material and process selection of passenger tire platform with fixed carcass (Goodyear).

The three cases, coming from the three industrial partners of the COMPOSELECTOR project are different enough to make the proposed BDSS applicable for a wide range of decision processes in the field of composite material design.

Further reading

BPMN helps model coating development processes

Cardanit helps optimize warehouse logistics processes

BPMN facilitates simulation-driven design engineering processes

Dario Campagna joined ESTECO in 2012 after earning a PhD in Computer Science. Starting as a Developer in the Research and Development (R&D) team, he soon took on roles as Scrum Master and Agile Coach, fostering continuous improvement across the organization and engaging in Business Process Management research. Since September 2021, he has been overseeing EU and regional projects, along with internal research initiatives, applying his expertise in agile methodologies. In 2023, Dario got promoted to Head of R&D.

Dario Campagna joined ESTECO in 2012 after earning a PhD in Computer Science. Starting as a Developer in the Research and Development (R&D) team, he soon took on roles as Scrum Master and Agile Coach, fostering continuous improvement across the organization and engaging in Business Process Management research. Since September 2021, he has been overseeing EU and regional projects, along with internal research initiatives, applying his expertise in agile methodologies. In 2023, Dario got promoted to Head of R&D.

Learn how to effectively represent data in your BPMN diagrams, create reliable data models and design processes that align with your organizational goals.

Do you know how to model data in BPMN?

Learn how to effectively represent data in your BPMN diagrams, create reliable data models and design processes that align with your organizational goals.

Do you know how to model data in BPMN?

Learn how to effectively represent data in your BPMN diagrams, create reliable data models and design processes that align with your organizational goals.