Saving time and effort in coating materials development with Cardanit BPMN editor

-

Organization: Smallmatek

-

Design challenge: Model the entire coating development process, from technical tasks to data handling

-

Benefits:

Cutting down the number of experiments and saving timeMoving from unorganized practices to formalized proceduresReducing the learning effort and the modeling friction

When it comes to complex decision processes involving multiple stakeholders from different departments, being able to keep all parts updated and streamline the sequence of tasks is essential for a smooth process.

This is the main reason behind the adoption of Cardanit BPMN editor by Smallmatek, Lda (SMT) within the framework of the EU-funded project VIPCOAT (GA number 952903).

Frederico Maia, General Director of Smallmatek, explains how they benefited from business process modeling in order to move from unorganized practices to formalized procedures for coating materials development. This allowed his team to spot inefficiencies and, consequently, to save a lot of time and effort.

The ContextTowards Business Decision Models and Machine Learning

Smallmatek is a Portuguese company that offers integrated solutions for the protection of metal structures against corrosion and biofouling failure, producing cost-effective and eco-efficient “smart” additives, and providing expert consulting services.

Smallmatek is also taking part in the EU-funded project VIPCOAT for the development of a business decision model for the selection and manufacturing of coating materials. The goal of the project is to create an open innovation platform that should assist engineers in developing coating materials and constructing accelerated life test scenarios to assess their durability, with an initial focus on the aerospace industry.

This platform will open the door for new production concepts with reduced process steps, lower consumption of energy and reduced natural resource utilization (water, raw materials). Machine Learning and physics-based modeling are combined to optimize industry-relevant active protective coating development processes.

The ChallengeFrom effective procedure to enhanced formalized processes

As part of the project, Smallmatek’s focus is to develop new anticorrosive pigments to be incorporated in a new coating for aeronautical application, avoiding waste of raw material and energy. This is usually done by doing experiments, but one of the project goals is to replace them with modeling and Artificial Intelligence.

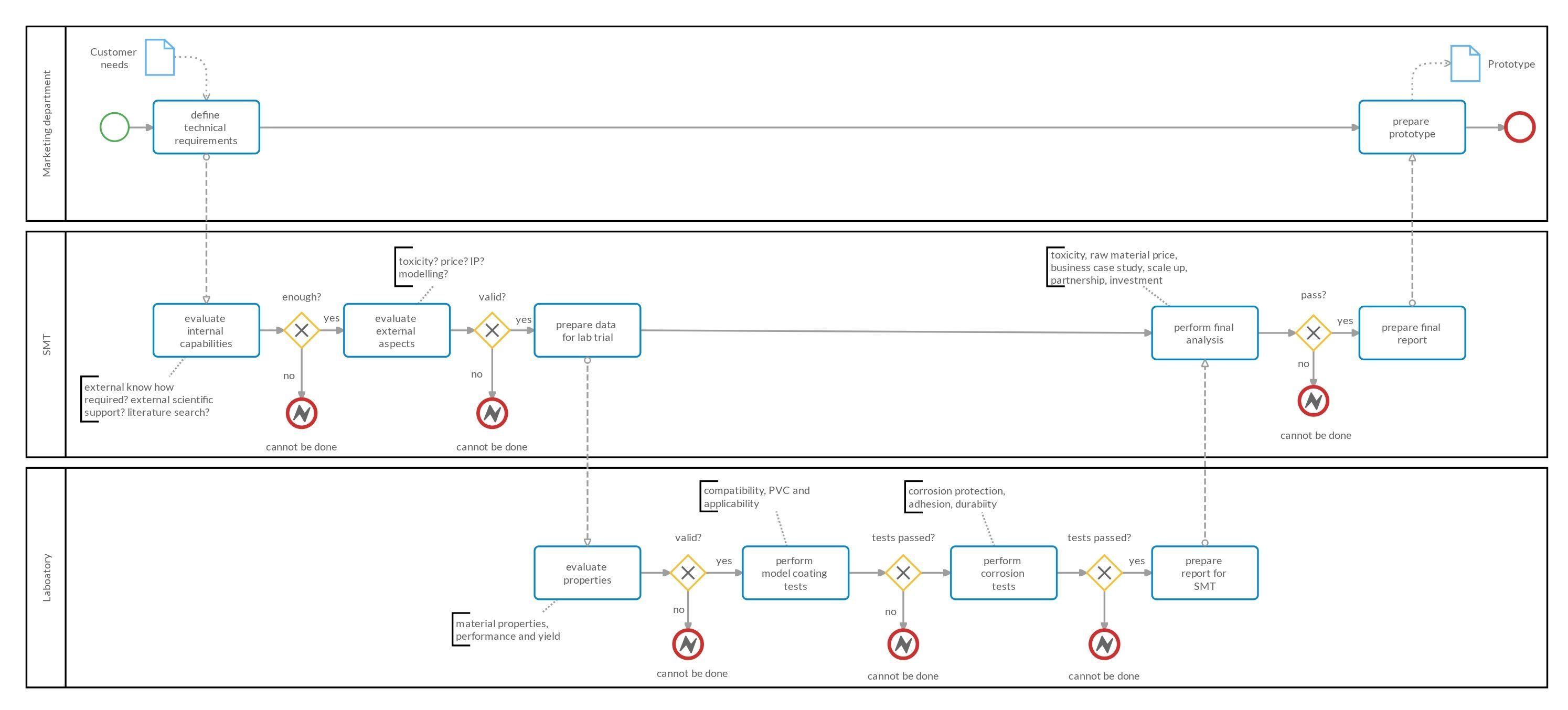

Another organization involved in VIPCOAT is LIST (Luxembourg Institute of Science and Technology), which has extensively used Cardanit in some of its works. LIST suggested using Cardanit to Smallmatek’s CEO Frederico Maia, to start modeling the whole process with BPMN (Business Process Model and Notation): from the business requirements for the new coating to the technical tasks, including data handling and result reporting. The process includes all stakeholders involved, coming from different departments.

The main challenge lies in expediting the whole process, taking full control of all procedures, identifying any areas of improvement and transferring valuable information to people and teams outside the Smallmatek organization.

The SolutionTranslating requirements and ideas into well-informed business decisions

Frederico started working with LIST to develop and organize workflows transferring his ideas into a scheme. He drafted some BPMN diagrams, shared them with Carlos Kavka, Group Leader at LIST, and worked together to map the as-is situation as well as a desired to-be version to be tested within the project.

Now that Smallmatek is halfway through the VIPCOAT project they realized that the clarity provided by the mapped processes helps them avoid some quite onerous sessions in the laboratory, potentially reducing the number of experiments required to reach the best coating anticorrosive pigment.

For this very reason, business decisions are taken based on the work done with Cardanit and this has become a huge step in organizing their workflows.

They could visually see all the steps of the process, what information is needed to move from the business requirements to the production process and what experiments are necessary. Process modeling combined with Machine Learning techniques allowed to speed up the process and avoid waste of time, moving from ten experiments to only two.

BPMN workflow with all departments involved in anticorrosive pigment development

The BenefitsSmooth modeling experience to focus on process improvements and collaboration

Frederico is very happy with the use of Cardanit. Although he never used it before, he found it very intuitive. He didn’t need to start looking for instructions and he didn’t waste any time learning a new tool.

He also discovered that Cardanit helped him organize his ideas in a more structured way. Now that he uses workflows he understands better how complex processes can be. Moving from unorganized practices, although well performing, to formalized procedures, allows to make them even more effective and efficient.

In addition, the fact that Smallmatek can now avoid lengthy experiments in the laboratory helps them save time, energy and resources. The time invested in process modeling is always well spent. With Cardanit, he didn’t need to learn how the tool worked, instead he could focus on the modeling process and how he could improve it.

“Using a tool like Cardanit, reduces both the learning effort and the modeling friction. This amplifies the ROI on process modeling”

Being able to collaborate with people both within and outside Smallmatek, was also essential to correctly model the process and identify bottlenecks and improvements.

Further reading

BPMN in industrial manufacturing: BPMN and DMN for better informed decisions in the composite materials design

BPMN in engineering: Why we chose to rely on BPMN for ESTECO Technology

BPM in logistics: Cardanit pivotal role in port logistics analysis and optimization

Dr. Frederico Maia is a Chemist with PhD in Materials Science and currently is the General Director of SMT. He has several years of experience in the development of nanostructured materials for immobilization and controlled release of active compounds, namely corrosion inhibitors. He has several peer-reviewed publications (> 30) and 2 patents in the area of materials chemistry and participated in several national and international R&D projects, some of them focused on multifunctional additives for multifunctional coatings development.

Dr. Frederico Maia is a Chemist with PhD in Materials Science and currently is the General Director of SMT. He has several years of experience in the development of nanostructured materials for immobilization and controlled release of active compounds, namely corrosion inhibitors. He has several peer-reviewed publications (> 30) and 2 patents in the area of materials chemistry and participated in several national and international R&D projects, some of them focused on multifunctional additives for multifunctional coatings development.

Learn how to effectively represent data in your BPMN diagrams, create reliable data models and design processes that align with your organizational goals.

Do you know how to model data in BPMN?

Learn how to effectively represent data in your BPMN diagrams, create reliable data models and design processes that align with your organizational goals.

Do you know how to model data in BPMN?

Learn how to effectively represent data in your BPMN diagrams, create reliable data models and design processes that align with your organizational goals.