A guided tour across Business Process Improvement: methodologies and steps

Written by Andrea

23 July 2025 · 12 min read

Organizations need to keep up with a dynamic and constantly changing market, where demands for high quality products and services go along with requirements for efficient support and customer service. Hence, both large international companies and small businesses need to focus on operational agility and overall performance increase.

Processes are key to this end, and being able to continuously improve them really makes the difference in this competitive arena. This is where Business Process Improvement comes into play. Choosing the methodology that best suits an organization's needs, following the right steps and involving the right stakeholders at the right time, is what really may help organizations excel in this ever-changing landscape.

What is Business Process Improvement and why it’s important

Business Process Improvement (BPI) is a systematic approach to analyzing and optimizing business processes to enhance efficiency, reduce costs, and improve the overall performance. The primary goal of BPI is to identify inefficiencies—whether they are bottlenecks, deadlocks or bad use of resources—and then redesign the process to improve it and solve all errors.

Processes are everywhere and are fundamental for every organization's operations. Whether they are internal processes—such as design or production processes, administrative or IT processes—or external—such as customer service or delivery processes, host reception or insurance funds—the more efficient they are, the better the entire organization performs. If your online check-in service has short downtimes, if the delivery requires more time than expected, if internal processes are usually broken by incorrect flow of information or late stakeholder involvement, chances are that the business operations are less effective. This is why BPI is important: it helps you get more control on your processes and thus be able to make them more efficient.

Business Process Improvement is a complex strategy that involves multiple steps and actions and that may be addressed using different methodologies. Each methodology focuses on different aspects and there’s no “one fits all”: based on the specific business need, business specialists can turn to some of them specifically.

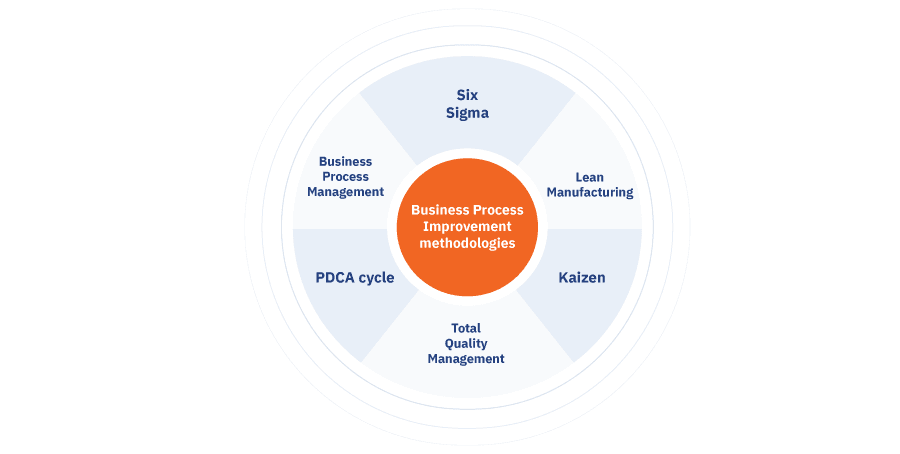

The most common Business Process Improvement methodologies

Let’s have a quick dive into the most common BPI methodologies and their characteristics.

Six Sigma

Six Sigma is a data-driven approach focused on reducing defects, minimizing variation, and increasing efficiency. To do this, Six Sigma uses the five stages of the DIMAIC technique:

- Define the problem and the opportunity for improvement.

- Measure the process performance.

- Analyze all data and find root causes.

- Improve the process by addressing the root causes.

- Control the process and maintain improvements.

Six Sigma is a good technique for companies needing quality control, consistency, and measurable outcomes. Indeed, it’s often used in manufacturing and was originally applied at Motorola and General Electrics.

Lean Manufacturing

The Lean methodology is based on reducing or even eliminating muda (Japanese for “waste”). By identifying and eliminating all additional non valuable activities, the objective of the Lean approach is to streamline organizations' processes, maximize customer value and reduce costs.

The principles for the Lean Manufacturing approach are:

- Identify product value: Identify the specific features or benefits that customers are truly willing to pay for.

- Map the Value Stream: Outline every step in your process and evaluate each to remove those that don’t contribute to the product value.

- Create Flow: Ensure a seamless movement of products through value-adding steps.

- Establish Pull: Produce only in response to actual customer demand, delivering exactly what they want, when they want it.

- Pursue Continuous Improvement: Regularly refine processes to boost efficiency and eliminate waste.

Lean Manufacturing originated at Toyota and it’s also known as “just-in-time production”. It is often applied where reducing waste is a paramount like in manufacturing and production industries.

Kaizen

Kaizen is a Japanese philosophy of continuous, incremental improvements involving all employees and different processes. The principle at Kaizen’s basis is the enhancement of every teams’ strength to achieve higher overall performance within the company.

The focus is on small frequent improvements that cumulatively bring improvement to the key business processes:

- Quality - increasing the quality of products, services and best practices

- Cost - optimizing costs for material, energy and resources

- Delivery - reduce delivery time

- Management - improve general management and documentation

- Safety - improving working conditions

Kaizen is a good methodology for companies amining at actively involving teams and that want to foster a culture of continuous improvement.

Total Quality Management

The Total Quality Management (TQM) methodology is a comprehensive management approach that involves everyone in the organization to improve processes, products, and services and achieve long-term success and customer satisfaction. The aim is to improve quality across all company activities. While other methods may focus on specific areas of improvement, the TQM considers the entire organization and sets high quality standards for every single function.

There are 8 principles driving TMQ, that are:

- Customer focus: putting customers’ needs first.

- Leadership: to establish an environment that fosters improvement from all actors.

- Engagement: to involve people at all levels to act.

- Process approach: formalizing and sharing processes within the organization.

- Improvement: as the base of quality increase.

- Evidence-based Decision Making: to base decision on data analysis.

- Relationship managemen: to make information flow to interested stakeholders.

- Systems Approach: to identify, understand and manage interrelated processes as a whole system.

This method is often applied in highly regulated industries where quality must be assured at all levels, such as pharmaceutical or food and beverage.

Plan-Do-Check-Act

The Plan-Do-Check-Act (PDCA) method is an interactive problem-solving and process improvement cycle. It’s also known as the Deming Cycle, and finds its basis on identifying opportunities, implementing changes, monitoring results, and making adjustments.

It involves four steps that are:

- Plan: identify opportunities and set goals.

- Do: implement actions on a small scale and test them.

- Check: analyze the results from the implemented actions.

- Act: further improve the actions to get even better results.

The PDCA method is a trusted methodology for organizations that can test improvements on a small scale before rolling them out at a larger extent.

Business Process Management

Business Process Management (BPM) entails a range of activities to progressively improve business processes and achieve larger business goals. It’s a very broad discipline that has the aim to oversee how work is performed in the organization and take advantage of improvement opportunities—for example, reducing costs, execution times, or error rates.

Business Process Management is usually represented as a cycle of five different phases, that are:

- Design: to understand how the process works and map it from beginning to end

- Model: apply changes to the process and design how you want the process to look like

- Execute: to turn diagrams into practice and see how changes perform

- Monitor: to decide if the applied changes are real improvements or not

- Optimize: to continue improve the process and achieve continuous improvement

BPM is a widely used method in organizations that need to automate and monitor business processes in real time or that need to centralize process management.

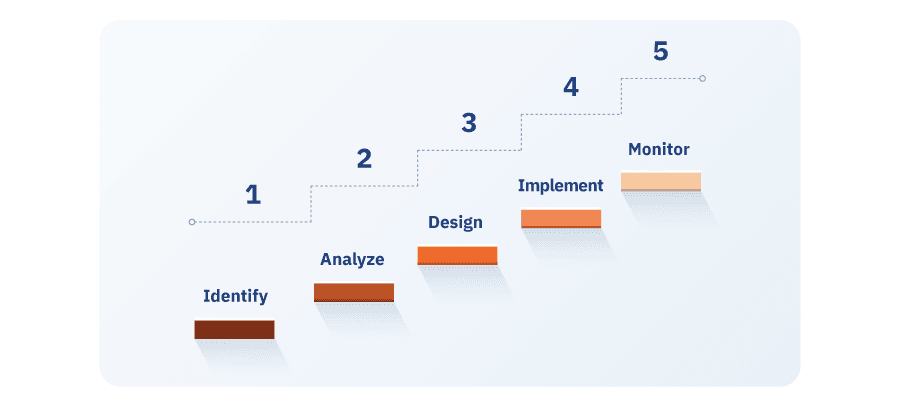

How to improve business processes step by step

Whatever Business Process Improvement methodology you choose, there are some common steps that you need to follow to improve your business processes.

1. Identify the problem

The first step is to look at the current business processes at a high level to pinpoint inefficiencies, bottlenecks, or pain points. You can do this through process audits, customer feedback, performance metrics, or employee input. Essential in this phase is to involve all stakeholders in order to get the full picture and be sure you are considering every aspect.

What you really need to do in this phase is to answer the right questions so that everything is clear and all details are investigated. In the chapter below we’ll go more in detail through this and you can find a list of some useful questions to consider.

2. Analyze the process

In this phase you need to clearly visualize every step of the current process (“as-is process”). Process mapping tools can help in this phase as they make the design activity smoother and help in getting a visual representation of how things work. In this step you need to consider all stakeholders and make sure you map every single activity of the process in the correct way. Starting from an accurate process model is essential to make sure everything that comes next is reliable. After accurately mapping the process you should be able to visually identify where bottlenecks, delays or any lack of performance occur in the process. The more information you are able to collect, the more precise your process model is and the more accurate your process analysis will be. To do so, you can add BPSim parameters and get your BPMN model even more detailed and reliable.

As said, process mapping tools are really useful in this phase and there are some functionalities that you can look at that really make this step easier. Here’s a list of the most relevant ones that you can find on Cardanit and that help you focus on the analysis phase rather than on the workflow creation task:

- Intuitive design: drag-and-drop interface and clean layout ensure you can create models quickly.

- Customization: to highlight the most important task in a process and make it easily readable.

- Auto-layout: to tidy-up your diagrams with just one click.

3. Design the improved process

Based on the analysis, redesign the process to eliminate inefficiencies (“to-be process”). Changes may involve how the process flows, when people are involved, how resources are allocated, how information and documents reach the right people. Ideally, you may also come up with different to-be versions of the process, with improvements involving different steps and areas of the process.

Essential in this phase is to measure potential improvements, perform multiple what-if analyses and balance costs and benefits to identify the optimal to-be process. To this end, you may benefit from Cardanit process simulation functionalities that enables you to identify bottlenecks, optimize resource allocation, and test different process configurations. Data analysis tools like heatmaps and bar charts in Cardanit can help in the evaluation phase.

4. Implement the redesigned process

After deciding on what to put into action, the time has come for its implementation. Changing processes within an organization, even the smallest ones, is never easy. Especially when people and systems are involved. That’s why the implementation phase of possible improvements is very costly and time consuming. The ideal approach is to start with a small pilot project to test changes and then gradually scale up to a broader environment. That’s why involving key stakeholders from the very beginning really makes the difference in facilitating the adoption of redesigned processes.

5. Monitor and track

Though the implementation part may seem the final stage, process improvement should be continuous. That’s why you need to monitor the performance of the new process, set specific KPIs to evaluate its effectiveness or new opportunities. Keep key stakeholders in the loop to get valuable feedback and be sure to consider new variables in the workflow that may affect its performance in the long-term.

This step-by-step approach aligns with the most common business process improvement methodologies and offers a structured way to enhance efficiency and quality at all levels - whether it applies to internal or external processes.

What questions you need to ask before starting a process improvement project

We’ve explored the different business process improvement methodologies and we’ve also summarized the steps you need to follow to improve process efficiency. But there’s one important step that should come even before anything else and that is crucial for the BPI project to be really effective. Before choosing the methodology, before choosing the tool, you need to ask (and answer) the right questions.

Asking the right questions is essential to make the purpose of the project clear, identify the stakeholders and specify the outcome to be expected. These questions apply to different categories and are all equally important.

Who should be involved in the process?

What’s the feedback we get from stakeholders?

Does a particular department own the process?

Whose approval will be needed?

How long will each part of the process take?

Where is the most time spent?

Where is the least time spent?

Which steps are necessary? Which are not?

How will this process be documented?

Where will it live for accessibility?

Are we committed to investing the necessary time and resources for this project?

What should we start, stop, and continue?

What are the first steps in implementing the new process?

How long will implementation take?

How will implementation success be measured and verified?

These are some examples of questions that you may need to answer. Of course, the more specific the questions are, the clearer the objectives, connections, and constraints will be. Often, you may feel eager to start mapping the process—to see it on paper and move on to the to-be phase—especially if you're facing a specific problem you want to solve quickly. However, skipping this initial phase can lead to more problems than progress, resulting in a poorly understood process with missing links and unclear goals. That’s why, regardless of the methodology you follow or the tool you use, ensuring that all necessary questions are thoroughly answered is the true first step toward business process improvement.

How simulation can boost continuous process improvement

Answer all necessary questions. Involve the right people at the right time. Clearly identify the process and thoroughly map it. Choose the methodology that best fits your needs and be sure to use a collaborative tool to draw your workflow, share it with your stakeholders, and comment on it.

Now that you’ve carefully modeled the current process, how can you be sure that you are working on an accurate and reliable digital replica of your process?

Using the BPMN standard is the first step towards a visually-clear and transparent representation of a process. BPMN workflows are simple to model and easy to understand also for non-experts. But, you can add complexity using process simulation and make sure you’re analyzing the process with all useful information at hand.

Process simulation adds depth to process modeling and allows you to test and analyze your process under various conditions.

Process simulation can be really useful in different moments of business process improvement.

Process simulation for the modeling phase

You can add details to your workflow during the as-is analysis phase: you can be sure you have all information about the time required by each task, all the resources involved, the probabilities at decision points, etc. This way you can be sure you are making data-driven analysis.

This phase is often called process validation and the purpose is to validate that the process behaves as expected and that important details are not missing.

Process simulation for the to-be process assessment

The second moment where process simulation can come into play during your process improvement project is before the implementation phase. You have modeled the current version of the process, you’ve analyzed it and then you’ve come up with a reviewed—and ideally improved—to-be process.

So you identified where resources could be allocated in a more effective way, you reviewed the process flow to cut extra costs and save time. Now should come the implementation. But do you know that this new to-be process will actually bring benefits and improvement? With process simulation you can simulate the new version of the process and have a data-based view on how the new process should actually perform. This is essential to eliminate the guesswork and move towards a data-driven approach.

How you can use Cardanit for Business Process Improvement

Now that we’ve gone through all the necessary steps of business process improvements, you should be ready to start analyzing and improving your processes. You have all the major methodologies to choose from, the steps that you need to follow and the questions you need to answer. Chances are that now you also need a tool to put everything together.

There are many tools out there that are great for modeling, you can also turn to some free online tools and start drawing your basic workflow. But, when it comes to creating visually clear workflows, sharing and collaborating with stakeholders, turning a workflow into a readable document, adding process simulation on top of your BPMN models, choosing the right tool can really make the difference.

Cardanit is a BPM software that covers all these requirements, and more. You can benefit from its intuitive interface and easy-to-use modeling functionalities to create your BPMN workflow, highlight the main tasks and collaborate with your team to make sure that every aspect is considered. Then, you can add BPSim parameters to your BPMN model and ensure your as-is model is as accurate as possible. You can then simulate possible to-be processes and analyze their impact to make data-driven decisions.

Here’s an overview of some of the main functionalities you can find in Cardanit. Start a full feature trial to try them and assess their impact on your projects.

Easily create professional BPMN workflows with a clean layout and user-friendly tools.

Turn BPMN workflows into readable reports, with full element details.

Track changes and manage different iterations on the same project.

Work with peers on the same BPMN workflow and ensure every aspect is correctly modeled.

Test multiple to-be processes and identify bottlenecks and areas of improvement.

Identify inefficiencies instantly with heatmaps and charts and make data analysis easier.

On a final note, Business Process Improvement plays a vital role in boosting operational efficiency and overall performance. Organizations of all sizes can benefit from our BPM software Cardanit to build precise "as-is" models and simulate "to-be" processes, enabling smarter, data-driven decisions.

Further reading

BPSim standard specification for parameterizing your model: definition and benefits

The five steps of the Business Process Management lifecycle

Process validation: how Process Simulation helps verify BPMN models

Andrea is the collective pseudonym for the group of people working behind Cardanit, the Business Process Management Software as a Service of ESTECO. The group has different backgrounds and several decades of experience in fields varying from BPM, BPMN, DMN, Process Mining, Simulation, Optimization, Numerical Methods, Research and Development, and Marketing.

Andrea is the collective pseudonym for the group of people working behind Cardanit, the Business Process Management Software as a Service of ESTECO. The group has different backgrounds and several decades of experience in fields varying from BPM, BPMN, DMN, Process Mining, Simulation, Optimization, Numerical Methods, Research and Development, and Marketing.

People also ask

Yes, these methodologies can often be combined to suit specific business needs. Many organizations use hybrid approaches—for example, blending Lean’s focus on waste reduction with Six Sigma’s data-driven analysis. The key is to understand your goals and select complementary elements rather than rigidly sticking to one method.

To choose between Cardanit and other BPM tools, consider what features matter most for your process improvement goals. Cardanit stands out for its easy-to-use interface, process simulation, and real-time collaboration, making it ideal for both beginners and experts. If you need more than just diagramming—like data-driven analysis and stakeholder engagement—Cardanit offers a comprehensive solution from modeling to simulation and analysis.

Yes, there are real-world case studies showing how Cardanit has helped organizations improve their business processes. In logistics, LIFT could evaluate different scenarios and find the most efficient transportation system using Cardanit. In healthcare, EUC Health Group used Cardanit for a merger project to map hundreds of processes quickly, aid collaboration, and continue optimizing workflows post-merger. In manufacturing, Inox Tech streamlined its pipeline production and interdepartmental flows by adopting Cardanit for BPMN mapping during its digital transformation.

A business is only as efficient as its processes. What are you waiting to improve yours?